Characteristics

MAGITEMP is a toughened glass which is made through heating ordinary annealed glass up to 650o C where it will be softened and then quickly soaked on both surfaces with a blast of cool air. Through this process, a stronger glass can be produced. This glass does not break easily under tension, and when it does break, it will shatter into small blunt pieces which do not harm people.

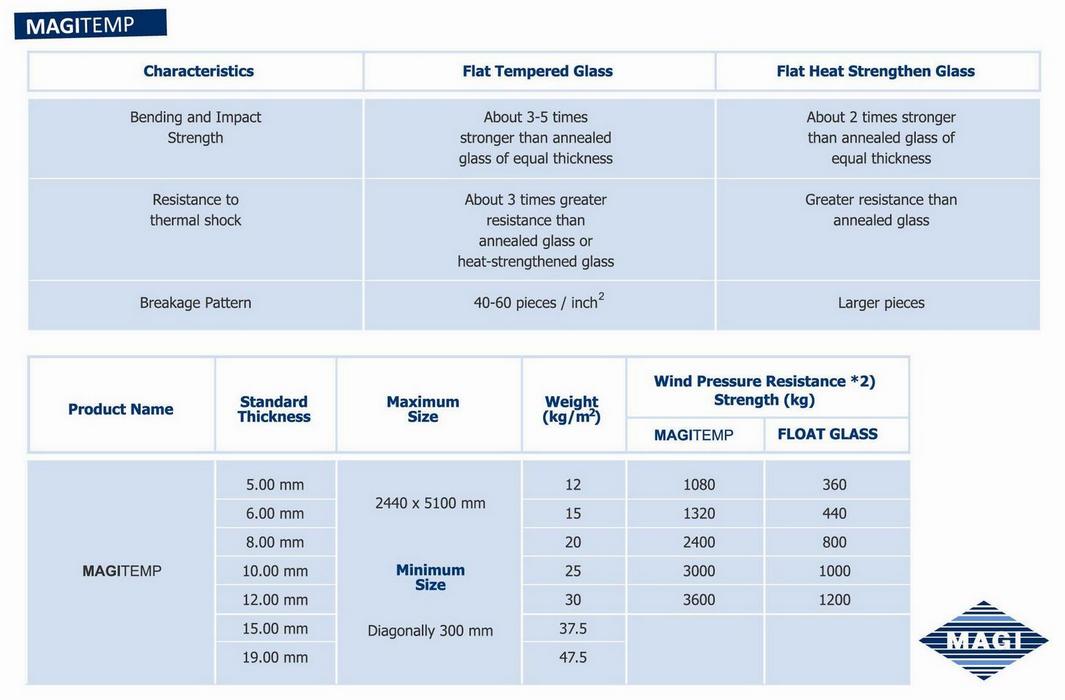

Because of its layered production process, MAGITEMP is definitely stronger than annealed glass, and it can withstand sudden temperature change up to 300o C. With our technology, we are able to produce a tempered glass which is stronger and safer for people and their environment compared to the annealed glass.

Benefits

MAGITEMP is safe for you, your family, employees, property, etc. Being 3 to 5 times stronger, it does not easily break and when it does, it will not harm people or property because it breaks into small blunt pieces that are harmless and easily cleaned.

MAGITEMP Heat Soak

Heat Soak is a process of heating toughened glass up to about 280o C in a chamber or oven. This process is done to elongate Nickel Sulfide (NiS) breaking point, therefore reduces the risk for glass breakage due to thermal shock in tempered glass, especially in areas that receive a frequent thermal shock such as canopy and spider fitted glass.

Nickel Sulfide (NiS) itself is a rare undetectable microscopic contaminant in raw materials of glass. The heating and rapid surface cooling that is undergone during glass toughening process is believed to change the Nickel Sulfide (NiS) from a stable to unstable state.

MAGI Heat Strengthen

Heat Strengthen process is similar as tempered glass process, except that the cooling process in heat strengthen is slower. Heat strengthen glass is two times stronger than annealed glass with equal thickness. It has higher tensile strength when subjected to greater wind loading. Also, it can withstand thermal shock better than annealed glass.

When heat strengthen glass breaks, it fragments into larger pieces and tends to stay intact in the break opening until replaced. Heat strengthen glass is particularly useful in spandrel or above ground floor panels since the broken fragments will not fall to the lower ground floor. High rise building with higher wind load can use a thinner glass to reduce building weight and glasses that used under higher thermal exposure, such as canopy glass.

Additionally, this process also diminishes the probability of glass’ spontaneous breakage caused by Nickel Sulfide (NiS).

Watch Our MAGITEMP Product Testing Video